LP 8970 E-AUT Series

For downloads see our downloads page for the LP 8970 E series.

Description

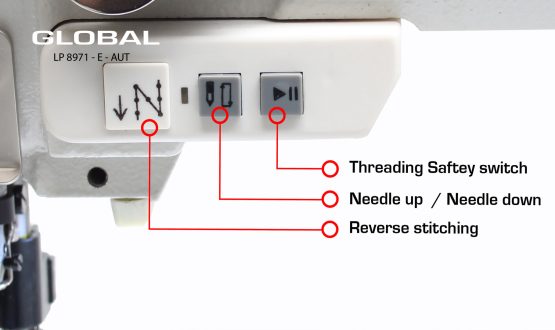

LP 8971 E-AUT

High speed, single needle postbed machine, with top driven roller, wheel- and needle feed and standard hook. Machine equipped with thread trimming device, automatic back tack and presser foot lift (all electric). The HMC direct drive mini servo motor, control box and control panel are integrated in the machine (All-in one).

LP 8971 E-LH-AUT

Same as a LP 8971 E-AUT, however equipped with large hook.

LP 8974 E-AUT

Double needle postbed machine, driven by HMC built-in mini servomotor, with wheel feed and top driven roller presser (no needle feed) and equipped with standard hooks, thread trimming device, automatic back tack and presser foot lift (all electric).

LP 8971 – E – ST – AUT

High speed, single needle postbed machine, with top driven roller, wheel- and needle feed and standard hook. Machine is equipped with thread trimming device, which can be adjusted easily, for short thread ends trimming, automatic back tack and presser foot lift (all electric).

Because of the unique thread trimming device, remaining thread ends are only 6 mm long. The HMC direct drive mini servo motor, control box and control panel are integrated in the machine (All-in one).

LP 8971 – E – NP – AUT

High speed, single needle postbed machine, with top driven roller, wheel- and needle feed and standard hook. Machine equipped with thread trimming device, automatic back tack and presser foot lift (all electric). Because of the unique thread trimming device, remaining thread ends are only 6 mm long. This newly designed machine has a small right post to make it suitable for easy sewing on children’s shoes.The HMC direct drive mini servo motor, control box and control panel are integrated in the machine (All-in one).

Our experience. Your succes.

In our 12,000 m2 headquarters in the Netherlands, we keep a large stock of sewing machines and spare parts and have a unique museum, which shows the history of the sewing machines over the last 180 years.

Global International BV is very proud of its own line of “Global” industrial sewing machines partially produced at our own facilities.

This sewing machine program contains over 400 different sewing machine types for the garment, automotive, leather and shoe industries. Global sewing machines stand for quality, durability and are always state of the art with the newest innovations in the branch!