Taking Control

“In recent years, we’ve witnessed a significant growth in the demand for automatic stitching machinery.

This trend has prompted Global International to make substantial investments in cutting-edge machinery.

Our aim is to better support our dealers and clients by ensuring we stay ahead of the curve in meeting their needs.”

.

YOUR BENEFITS

Finding precision in sewing has been a challenge? If you’re seeking a solution to automate the sewing process for your products, you can rely on us!

Global stands out by offering its clients advanced automation solutions in sewing, spanning various sectors such as footwear, apparel, and, particularly, Industry 4.0. We are committed to aiding in the development of templates for sewing on equipment, thereby contributing to efficiency and quality in production.

With extensive experience in automating stitches across a variety of materials, including footwear, bags, and other leather articles, as well as more challenging materials to sew, such as inconsistent products or those made of plastic and other compounds. Regardless of the area to be sewn, our team is ready to provide personalized and innovative solutions.

Count on Global’s expertise to drive automation in sewing, delivering not only precision but also efficiency and quality in your production processes. We’re prepared to turn challenges into solutions, raising the standard of your production.

Improving are process

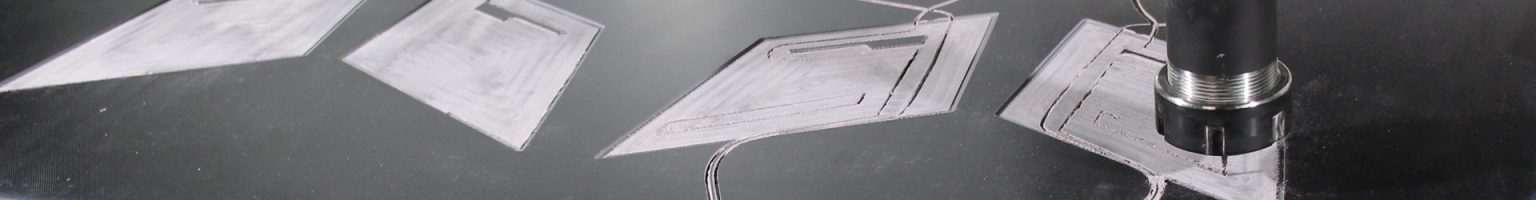

“Our experience combined with advanced technologies, such as CNC, 3D printer and Laser, allows us to create high-quality tools for unique projects.

We emphasize the importance of manual skill, which plays an essential role in the uniqueness of each task.

We value the balanced combination of manual work and the precise use of technology, ensuring efficiency in development.

Our commitment is to provide the best service, where expertise, manual work, and technology come together to elevate the quality of each project.”

customisation

“Global’s machines stand out for providing robust and reliable performance, as well as being highly adaptable. Each machine can be customized according to the specific needs of every client, emphasizing our commitment to delivering industrial solutions that surpass expectations.”

how to proceed

Are you interested in automating a sewing process? If so, please keep in mind the following necessary steps:

-DXF File: A DXF file containing all pieces to be sewn, correctly positioned, must be provided. This file should also include the sewing lines for the project to be executed optimally.

-Sewn Sample: A sewn sample of the product should be provided to facilitate a comparison between the current process and the final result. Additionally, 10 to 20 pairs of test samples are recommended, depending on the product’s complexity.

-Additional Information: Furthermore, essential details are needed for project development, such as needle size, bobbin and needle thread thickness, stitch size, and, in the case of closed-seam sewing, the starting point.

Without the provision of any of the above items, it will not be possible to assess the feasibility of the process and/or provide any estimates. We are committed to ensuring an efficient and high-quality project, and your collaboration in this process is crucial for the successful automation of the sewing process.

Parts

Our clamps are crafted from fiberglass and/or aluminum, ensuring durability and precision. Small accessories such as hinges and handles are produced in-house using 3D printing technology. The closure devices are made from galvanized material, ensuring resilience for our templates.